Energy

Energy from Waste

technology to Australia and New Zealand.

Based in Switzerland and Germany and with a worldwide network of partners, Renergon has been rolling out its patented RSD technology for dry fermentation – delivering great economic and ecological outcomes.

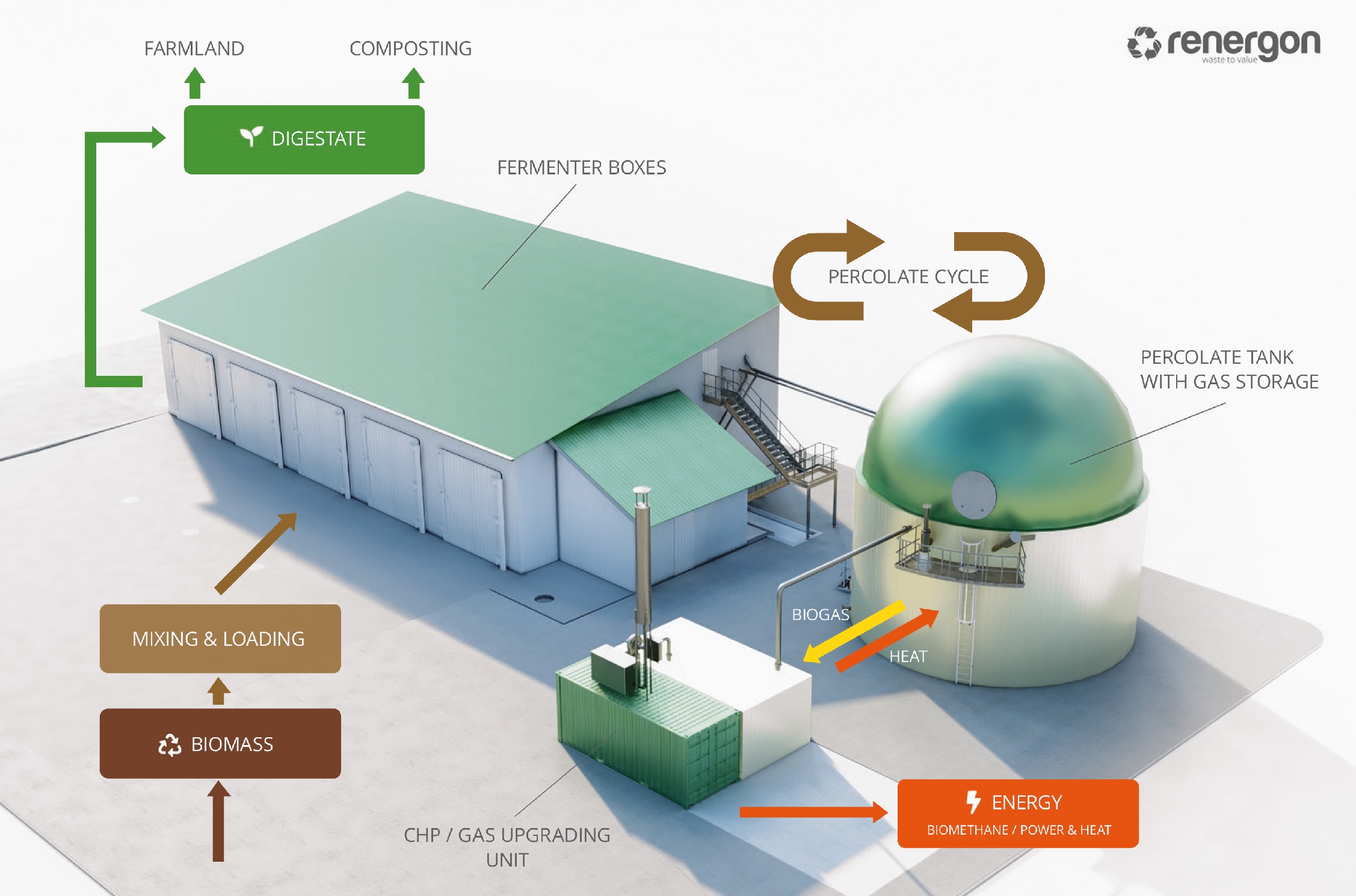

Where traditional liquid biogas plants and plug flow designs end, Renergon’s RSD® (Renergon Simultaneous Digestion) technology picks up. Dry fermentation uniquely empowers the processing of dry and fibrous materials (with a dry matter content of 20%-55%), which commonly challenge other systems.

Embracing a batch mode process, the system assures a steadfast biogas yield. The setup comprises multiple digester boxes (garage digesters), operating in a fixed fill-and-empty cycle.

Minimal manual intervention is needed, aside from elementary loading and unloading tasks, and substrate pre-treatment (like shredding) is seldom required. Moreover, the substrate remains unmoved during the entire retention period (18-21 days), reducing technology failure and maintenance costs by foregoing sensitive stirring and pumping mechanisms (preventing floating and swelling layers).

A standout benefit of dry fermentation is its minimal substrate requirements. Substrates can contain impurities, which remain as residues post-process and have less dependency on particle size and fibre content. Picture domestic biowaste, often inclusive of residual materials like packaging, or horse manure with horseshoes or holsters, which can severely damage stirrers.

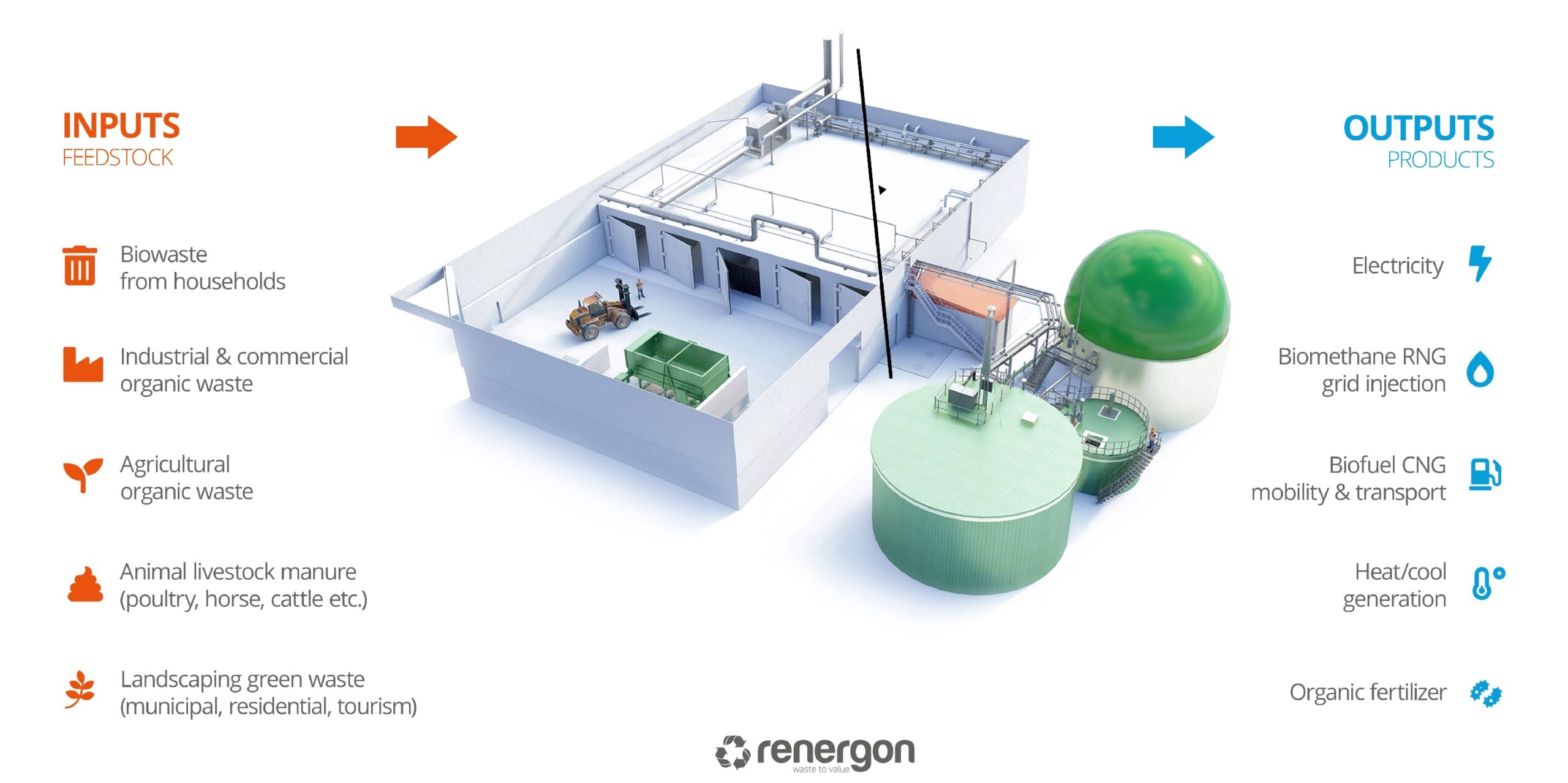

The generated biogas can be directly converted into electricity or refined into biomethane or bio natural gas, subsequently being integrated into the gas grid or utilized as vehicle fuel (CNG). It also produces high value fertilisers, compost and biochar, as well as revenues from waste disposal and procured carbon credits.

Globally, the potential of organic waste is often undervalued both economically and ecologically. With our partners, ITSG is able to turn this extensive range of material into value, providing organisations with both economic and technical advantages. Relevant substrates include:

• Biowaste (Food waste)

• Green Waste (Green and Grass cuttings, garden waste etc)

• Household or Municipal Waste

• Agricultural Waste (Production and processing waste, crop residues)

• Animal Husbandry Waste (manure from horse, poultry, cattle and pig farming)

• Slaughter by-products (waste from animal processing).

Hydrogen from Ethanol

The move to hydrogen power has been boosted following the release of details about a new hydrogen production device, developed by a Shanghai-based technology R&D group, and available in Australia and New Zealand through ITSG.

The catalytic dehydrogenation process uses bioethanol as a renewable resource to produce hydrogen and has the potential to revolutionize the way in which power is supplied and vehicles refueled.

For many years there have been significant challenges associated with the storage and distribution of hydrogen, principally for safety reasons. However, our Shanghai-based technology partners have developed an effective solution to these issues, whilst also satisfying the demands of a low carbon energy future.

The technology revolves around the construction of a small device that generates hydrogen instantaneously through a catalytic conversion of liquid fuels with high density energy. Tests carried out in China successfully demonstrated that the process of converting industrial ethanol by chemical plant, and ethanol raw materials by biological fermentation remains stable when run

continuously through the device.

This catalytic dehydrogenation process for producing hydrogen compares favourably against other hydrogen production methods, with low energy required, no carbon monoxide recovery or carbon

dioxide emissions, or other environmental pollution problems. The by-product, ethyl acetate, is also easy to be recovered and has a high utilization value as an important chemical raw material. The

small hydrogen production device is especially suitable for power stations in remote areas and potentially for the future refuelling of hydrogen-powered vehicles.